Our solutions ensure that all GxP-regulated systems, equipment, and facilities

perform reliably and meet international regulatory requirements including FDA,

EU GMP, WHO, and PIC/S guidelines.

Our Qualification & Validation Services

Facility & Utility Qualification:

Cleanroom & HVAC validation

Compressed air, WFI, RO, and purified water systems

Temperature, humidity & differential pressure mapping

Environmental monitoring support

Equipment Qualification (IQ, OQ, PQ):

Installation, operational, and performance qualification

Manufacturing & packaging equipment validation

Laboratory instrument qualification (HPLC, GC, balances, etc.)

Calibration documentation & traceability

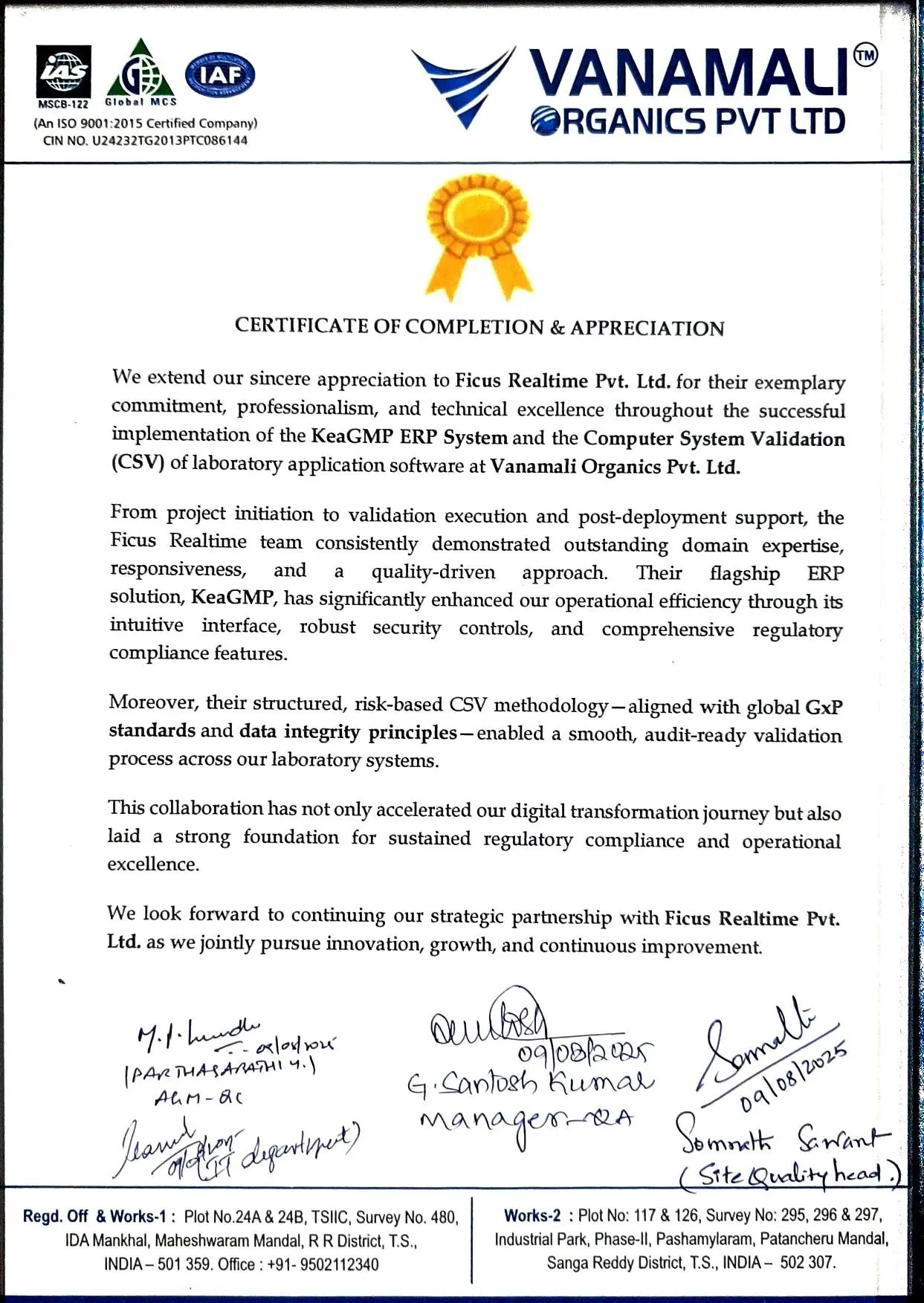

Computer System Validation (CSV):

Validation of GxP-critical software and systems

Part 11 & Annex 11 compliance

GAMP 5 risk-based validation lifecycle

Validation Master Plans (VMP), URS, IQ/OQ/PQ, and traceability

Process & Cleaning Validation:

Process validation for manufacturing & compounding

Cleaning validation for critical equipment

Hold-time studies and swab testing protocols

Compliance with ICH and FDA process validation stages

Revalidation & Lifecycle Maintenance:

Periodic review of validated systems

Requalification after changes, upgrades, or failures

Controlled change management with impact assessments

SOP support and audit trail documentation