Pharma

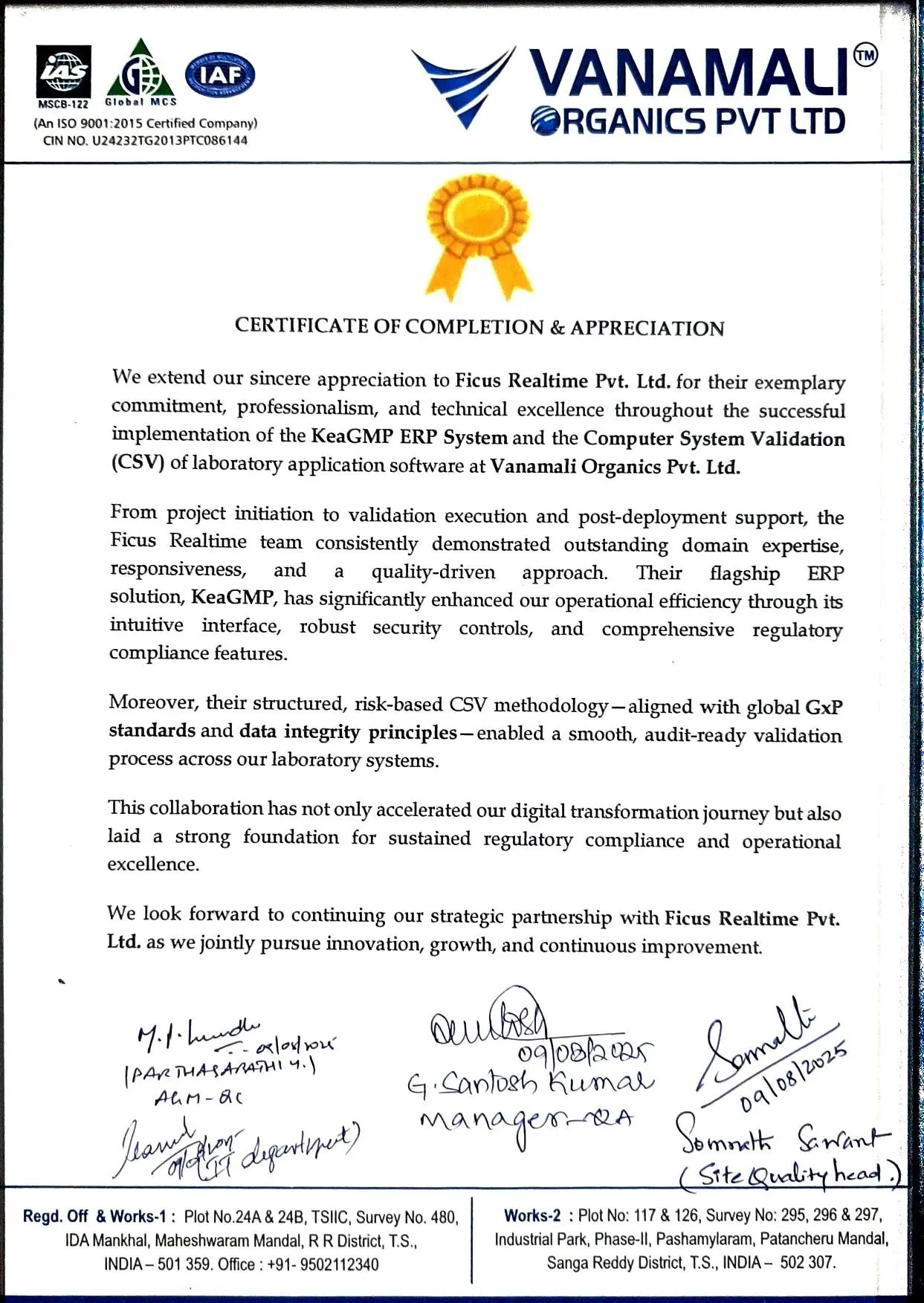

The pharmaceutical industry faces significant challenges without an ERP system, including regulatory non-compliance, data integrity risks, inefficient inventory management, and poor batch traceability. Disconnected operations lead to communication gaps, slow product development, and inconsistent supply chain management, ultimately increasing operational costs and compliance risks. Additionally, the lack of real-time insights hinders informed decision making, causing delays and inefficiencies. KeacGMP solution from Ficus Realtime, effectively resolves these issues by streamlining operations, ensuring regulatory compliance, enhancing traceability, and optimizing resource management—enabling pharmaceutical companies to achieve efficiency, quality, and audit readiness.

.jpg)